Сonnecting elements of pipelines

Services for the production of connecting elements of pipelines.

Our company has a long partnership with manufacturers of pipeline components.

Based on your orders, at the enterprises of our partners, the connecting parts of pipeline components can be made:

- bends are steeply curved, bends are bent;

- tees stamped and stamped;

- transitions are stamped and stamped, transitions are turned;

- stamped bottoms, transition rings, fittings;

- welded flat flanges with connections.

All products are made from low-carbon, alloyed and high-alloy steel.

Pipeline fittings are manufactured for: main, field and process pipelines for oil, gas, steam and hot water.

It is also possible to manufacture installation assemblies for pipelines, mobile and fixed supports for pipelines, products for heat and power facilities and other metal structures.

Our partners’ enterprises have mastered the application of fasteners and other metal structures of external anticorrosion coatings based on liquid two-component materials (polyurethane, modified polyurethane, epoxy, epoxy-polyurethane, based on polyurea) and thermal insulation of polyurethane foam in a protective waterproofing sheath.

The production of pipeline components is certified in accordance with the requirements of standard 9001-2011 (ISO 9001: 2008)..

The central factory laboratory of the enterprise is equipped with high:

- tech equipment for carrying out various types of testing and control of the base metal, welded joints, anti-corrosion coatings and thermal insulation: – non-destructive testing (visual measuring, penetrating substances (capillary), ultrasonic, radiographic and electric, magnetic);

- destructive control (mechanical statistical, mechanical dynamic, technological and special tests, measurement of hardness). The laboratory analyzes the chemical composition of metals and alloys using a PMI-MASTER portable multibasic optical emission analyzer in the UVR OXFORD INSTRUMENTS ANALITYCAL package.

Labor analüüsib metallide ja sulamite keemilist koostist, kasutades PMI-MASTER kaasaskantavat optilist emissioonianalüsaatorit UVR OXFORD INSTRUMENTS ANALITYCAL pakendis.

| Part name | Diameter mm | Length mm | Width mm | Height mm | Weight kg |

|---|---|---|---|---|---|

| Bent tap | 76 | 1467 | 627 | 76 | 30 |

| 325 | 3270 | 1176 | 325 | 1020 | |

| 530 | 4830 | 1444 | 530 | 2456 | |

| OKSH | 108 | 288 | 136 | 108 | 2,5 |

| 325 | 866 | 409 | 325 | 150 | |

| 530 | 1435 | 672 | 530 | 440 | |

| Tee | 76 | 280 | 76 | 178 | 5,0 |

| 325 | 440 | 325 | 365 | 114 | |

| 530 | 800 | 530 | 565 | 168 |

Application for production of elements of pipelines.

You can fill in the application form here.

| The name of detail | Literal designation | Sketch | Purpose |

|---|---|---|---|

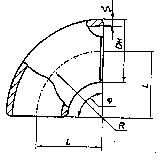

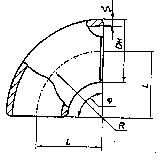

| Forged bends stamped, including made by hot broach on the horn | ОКШ |  |

Pipeline rotation |

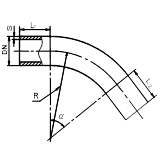

| Hot bend taps made by the method of bending using induction heating | ОГ |  |

Pipeline rotation |

| Stamped tees made of seamless or electrically welded pipes | ТШ |  |

Pipeline branch |

We are ready to discuss any terms of production of products according to the wishes and requirements of the Customer.

Toodete tellimisel vastavalt spetsifikatsioonile tuleb märkida:

- diameter;

- edge thickness (of the pipe to be attached);

- operating pressure;

- coefficient of working conditions (0.6 or 0.75);

- climatic performance;

- workspace.